- Calcium Carbide

- Calcium Cyanamide

- Dicyandiamide

- Electronic grade Dicyandiamide

- Cyanamide

- Creatine monohydrate

- Aminoguanidine bicarbonate

- Sarcosine

- Creatine Monohydrate

- Creatine

- Creatine HCL

- Creatine Nitrate

- Creatine Ethyl Ester Hydrochloride

- Creatineorotate

- Dicreatine Malate

- Tricreatine Malate

- Di-creatine Citrate

- Tricreatine Citrate

- Creatinine

- Creatine Alpha- Ketoglutarate

- Creatine Gluconate

- Creatine Ethyl Ester Malate

- Creatine Pyruvate

- Magnesium Creatine Chelate

- Creatine Phosphate

- Dicyandiamide-Industrial Grade

- Guanidineacetic Acid

- β-Guanidinopropionic acid

- Guanidine Hydrochloride

- Guanidine Carbonate

- Guanidine Nitrate

- Nitroguanidine

- 1-Methyl-3-Nitroguanidine

- Dicyandiamide-High Purity

- Micro-Dicyandiamide

Position: Home > Products

Position: Home > Products

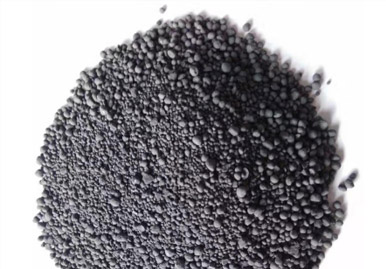

Product name: Calcium Cyanamide

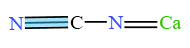

Molecular formula: CaCN2

Structural Formula:

CAS: 156-62-7

Molecular weight: 82.12

Calcium Cyanamide is a kind of black-gray oily particles with the odor of Calcium Carbide. It is a soil purifier for both medicine and fertilizer. It has the dual functions of soil disinfection and soil fertility improvement. Calcium Cyanamide produces cyanamide and dicyanamide when it meets water, which can kill harmful pathogens and nematodes.

Calcium Cyanamide is an alkaline fertilizer and one of the main raw materials for producing carbendazim pesticide with high efficiency and low toxicity. It can be used as herbicide, bactericide and insecticide to prevent the spread of schistosomiasis, root rot, rust and white mold, and can kill snails and ants. It can also be used as a defoliant for cotton and as a soil improvement agent. It is the basic raw material of organic synthesis industry and plastic industry, and can be used to produce Dicyandiamide, melamine and cyanogen melt.

Product Process:

Calcium Cyanamide is prepared by crushing Calcium Carbide, fluorite and Calcium Cyanamide, and spraying them into the rotary furnace (with high-purity nitrogen) for nitriding reaction. The process can be divided into the following four processes.

1. crushing large blocks of Calcium Carbide, proportioning by a weightless scale, automatically measuring Calcium Carbide, recycled Calcium Cyanamide and fluorite by using a DCS automatic control system respectively, and then grinding the calcium Carbide, the recycled Calcium Cyanamide and the fluorite into furnace charge by a ball mill.

2 . After the furnace charge is controlled and measured by the converter microcomputer, nitrogen is injected into the rotary furnace for nitriding, and the reaction formula is as follows:CaC2 + N2 = CaCN2 +C+7200 calories

3. Crushing and ball milling of Calcium Cyanamide particles.

4. The finished product is packaged and put into storage.